Iso Resin

Price 140 INR/ Kilograms

Iso Resin Specification

- Type

- Iso Resin

- Grade

- Industrial Grade

- Purity(%)

- High

- Application

- Industrial

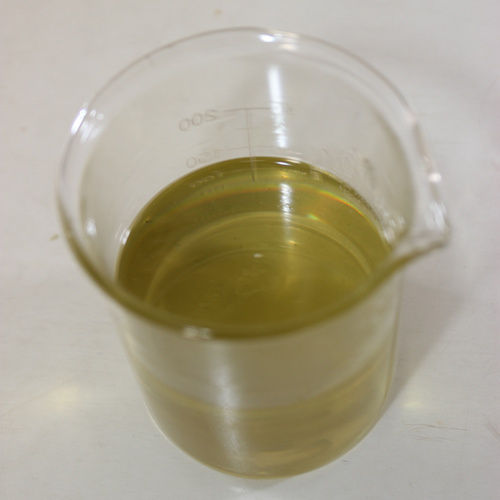

- Color

- Clear

Iso Resin Trade Information

- Minimum Order Quantity

- 35 Kilograms

- FOB Port

- AHMEDABAD

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5000 Kilograms Per Day

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About Iso Resin

Description

3201 is an isophthalic based resin. This resin is suitable for high mechanical strength applications as well as for good weathering and chemical resistance properties.

We recommend UV stabilization of resin for outdoor applications. Please note that UV stabilization of resin increases the curing time and also affects the mechanical strength.

Application

- 3201 is suitable for all hand lay up applications.

- 3201 can be used for applications requiring high mechanical strength, like abrasive wheels, FRP structures that need to bear mild loads on a continuous bases, etc.

- 3201 can also be used for applications requiring weather resistance like manufacturing boats, parts of discharge water treatment plants, etc.

- 3201 can also be used for applications requiring chemical resistance, like for anti corrosive linings, linings in chemical tanks, chemical tank manufacturing, etc.

Physical data in the liquid state (conforms to IS 6746 -1994)

|

Property |

Unit |

Limits |

Test method |

|

Appearance |

|

Pale Yellow clear/hazy liquid |

|

|

Specific Gravity |

|

1.100-/+0.05 |

|

|

Viscosity at 25 deg C - Brookfield LVT (2/30) |

Mpa.s (cPs) |

650-/+50 |

|

|

Acid Value |

Mg KOH/g |

14-/+4 |

|

|

Non-Volatiles Content |

% |

68-/+2 |

|

|

Gel Time 30 deg C |

Minutes |

15-/+5 |

|

|

Peak Exotherm |

Deg C |

200-/+10 |

|

|

Stability in the dark at 25 deg C |

Months |

3 |

|

|

Barcol Hardness |

|

40 (Min) |

Tested on casting of pure resin without any fillers or mats |

|

HDT |

Deg C |

95 (Min) |

|

Using 1.5%Co (3%), 1.5% MEKP (50%)

Post curing 1 / 2 Mature the laminate for 24 hours at room temperature, followed by post curing at 60 deg C for 16 hours or at 80 deg C for 3 hours.

Usage

- BITCT-3201 performs best if the laminate is completely post cured.

- If the Cobalt based accelerator of 3% concentration is used along with MEKP of 50% peroxide content as catalyst to cure the resin, then the optimum ratio of the accelerator and catalyst to be used is 1.5% (V/W) of the resin being used. However, this quantity of catalyst and accelerator may be adjusted to get the optimum gel time.

- Since viscosity increases on the storage due to styrene evaporation, styrene may be added to lower viscosity.

Storage BITCT-3201 remains stable for 3 months at 25deg C in the dark. The stability deteriorates markedly at elevated temperatures, especially when exposed to direct sunlight.

Packing BITCT-3201 is packed in HDPE carboys (35 kg) & epoxy coated steel drums (225 kgs)

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Resins Category

GP Resin

Price 114 INR / Kilograms

Minimum Order Quantity : 35 Kilograms

Purity(%) : High

Application : Industrial

Type : Other, GP Resin

Grade : Industrial Grade

Clear GP Resin

Price 122 INR / Kilograms

Minimum Order Quantity : 35 Kilograms

Purity(%) : High

Application : Industrial

Type : Other, Clear GP Resin

Grade : Industrial Grade

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free